Improving Truck Ergonomics Enhances Operator Productivity & Safety

Buying and spec’ing trucks to meet the diverse operating needs of your entire workforce is a challenge. You can spec your fleet to a “bell curve” and deal with the exceptions on either end of the spectrum by adding ergonomic-friendly upfit equipment or swapping a driver from a large to a small truck or vice versa.

Ergonomics must be high on the fleet manager’s “radar screen” because it can significantly impact the bottom line by reducing workers’ comp costs, improving driver productivity, and reducing fatigue-induced operator errors that can lead to preventable accidents.

The best way to spec more ergonomic vehicles is by proactively identifying existing and potential issues and rectify them before they impact morale, or, in worst-case situations, result in injuries. In addition to health issues, poor ergonomics is a key contributor to preventable accidents. Poor ergonomics reduces driver comfort, which increases fatigue, a key contributor to preventable accidents. Ease of use and operator safety must be your fundamental goal. Work closely with field workers to analyze their normal work processes, especially if they repeatedly climb into the rear of a service body or van for parts or equipment.

Sometimes vehicles are modified in the field without informing the fleet manager. Typically, the home office is not aware of the modification until there is an issue, such as when someone complains of an ergonomics-related health issue, or an accident occurs.

Field workers should regularly inspect vehicles and upfitted equipment to ensure they are in a safe working condition. These guidelines should also require employees to report any equipment failure or damage.

Fleets often find themselves defending upfit specifications against negligence allegations that result from pushing, pulling, lifting, or bending injuries. When there are complaints about “less-than-ergonomic” upfit decisions, it can result in expensive litigation.

Regardless of the vocational segment, fleet managers must ensure upfits will be ergonomically safe for operators over the service life of the vehicles. This is a perennial concern for HR managers, who regularly deal with workers’ compensation claims made by fleet drivers and equipment operators.

Over the years, work trucks and vans have evolved into mobile offices equipped with a variety of in-cab devices, such as mobile data terminals for job-site reporting, routing, and work orders, along with in-cab filing bins and swivel writing boards, all of which have dramatically enhanced driver productivity. However, these devices and equipment also takes up space, creating an increasingly cramped cab environment, restricting a driver’s body movements, which can potentially lead to ergonomic injuries.

While in the field, employees must often input data using a smaller keyboard or touch screen, while sitting in a congested truck cab that is often more constrained than a typical office workstation. In recent years, there’s been a steady stream of drivers claiming carpal tunnel syndrome as they spend more time typing on a keyboard in a cramped vehicle cab. Without adequate workspace for wrist supports and other ergonomic accessories, drivers are at risk of developing wrist strain or carpal tunnel syndrome.

Specifying Ergonomic-Friendly Equipment

When selecting upfit equipment, review vehicle requests from the field by focusing on ergonomic solutions, such as evaluating user body postures to understand the health implications of the work environment.

Ask follow-up questions of operators to verify the equipment is suitable for the job. It is important to continually train all employees handling equipment in its operation and safe use, especially if your company has high employee turnover. Also, user group field managers should regularly inspect equipment to ensure it’s in a safe working condition and that equipment is used only for its intended purpose. Develop written guidelines covering vehicle and equipment usage and instruct operators to follow manufacturer guidelines to avoid preventable accidents.

- Hydraulic Drop-Down Ladder Rack: Specify drop-down style ladder racks for vans. This helps minimize possible back problems that could arise from removing a 24-foot extension ladder from the roof of a van while improving operator efficiency.

- Roll-Up Doors: A cargo body with a roll-up door needs a pull-down that can be reached from the ground.

- Rear Step Bumper and Grab Handle: Analyze ease of rear entry and egress from service bodies and vans. Most fleets add a step bumper and a grab handles to facilitate getting in and out of a service body bed. To minimize slips, fleets are opting for an open strut-style rear bumper to allow snow or rain to fall through the openings and not collect on the bumper. Another consideration is side steps on pickups to access cross-bed toolboxes.

- Safety Tread Step: An open safety tread step is preferable to closed running board steps, especially in areas where snow collection can create slippery conditions. If there’s any chance a user will walk on a surface or use it as a step, it must not be smooth –an anti-slip coating or surface treatment is needed.

- Liftgates: A liftgate reduces the risk of overextension or back injuries by allowing users to more easily maneuver, load, and unload heavy products in and out of trucks, vans, or trailers.

- Slide-Out Bed: Specify bed sliders for pickups equipped with commercial-style caps, so the user doesn’t have to bend or twist to remove a heavy object from the vehicle bed.

- Side-Door Access: Walk-ins vans with side door access enables the user to work inside the body during inclement weather.

- Pull-out Ramps: These ramps expedite the removal of product loaded on a dolly. Consider ventilated-style pull-out ramps that stop snow and rain from collecting on the surface of the ramp.

It is important to realize that a “one-size-fits-all” approach to fleet specs is an ergonomic minefield with litigious consequences.

Let me know what you think.

Written by: Mike Antich mike.antich@bobit.com

Latest Resources

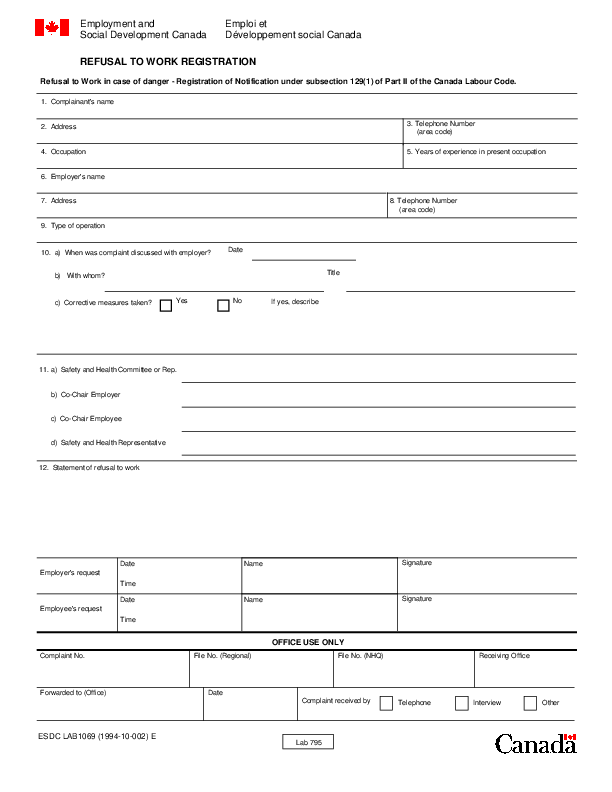

LAB 1069-Refusal to Work Registration

The Employer’s Investigation Report (LAB1069) is a required form under Part II of t ...

Joint Health and Safety Committee Evaluation Tool

This evaluation tool helps assess the effectiveness of a Joint Health and Safety Comm ...