When to Lift: That is the Question

“An ounce of prevention is worth a pound of cure.” Think ahead about how to manage moving loads.

As a professional driver, one task you will face, at one point or another, is manual material handling. With the variety of cargo that’s transported, the likelihood of helping to carry boxes, small construction tool attachments, or even cargo securement tools is likely. The most common overexertion injuries sustained by truck drivers involve the neck, shoulders, and back. After spending hours driving sitting mostly in a stationary position, the burst of strenuous activity involved in lifting can cause injuries. Carriers and operation staff can help mitigate how much manual lifting is done by the driver.

When a carrier and their operations staff are planning loads and interacting with customers, they should ask whether there will be assistance for their driver to unload/load the cargo safely. This question can apply to most cargo that is being transported by truck or on a trailer. Figuring it out ahead of time helps eliminate unsafe lifting that may otherwise be expected to be done by the driver.

Drivers also need to manage themselves when it comes to manually lifting cargo during their work shift. Before lifting, drivers should take steps to prevent an injury or damage to the cargo. First, look at what needs to be lifted, and then ask: “Can I lift this piece of cargo safely?” Secondly, look at the object(s) to be lifted, and ask:

• How heavy is it?

• How far do I need to carry it?

• What are the ground conditions where I will be lifting and carrying?

If you are unsure that you can lift and carry the cargo safely, ask for help!

Drivers can be proactive in preventing injuries by limiting the amount of lifting they do. During a driver’s work shift, there are common cargo securement tools that drivers need to lift, such as straps, chains, boomers, and load bars. These tools can be quite heavy and awkward. Each load can require different cargo securement tools and it can be quite exhausting lifting and carrying multiple chains and boomers down a 53-foot trailer.

To help prevent injuries, such as a strained back or a rolled ankle, drivers should plan:

• While walking up to the truck or trailer, confirm what cargo will be loaded

• Confirm what cargo securement tools will be needed

• When possible, place the cargo securement out before the cargo is loaded

Setting out cargo securement tools ahead of time helps reduce the risk of injury from lifting heavy chains repeatedly and carrying them across uneven ground. The same approach applies to unloading cargo.

Remember that manual lifting injuries can be avoided by slowing down, asking the right questions, and most of all, asking for help when it is needed. Employers, supervisors, and drivers share the responsibility to avoid injury caused by manual material handling.

Latest Resources

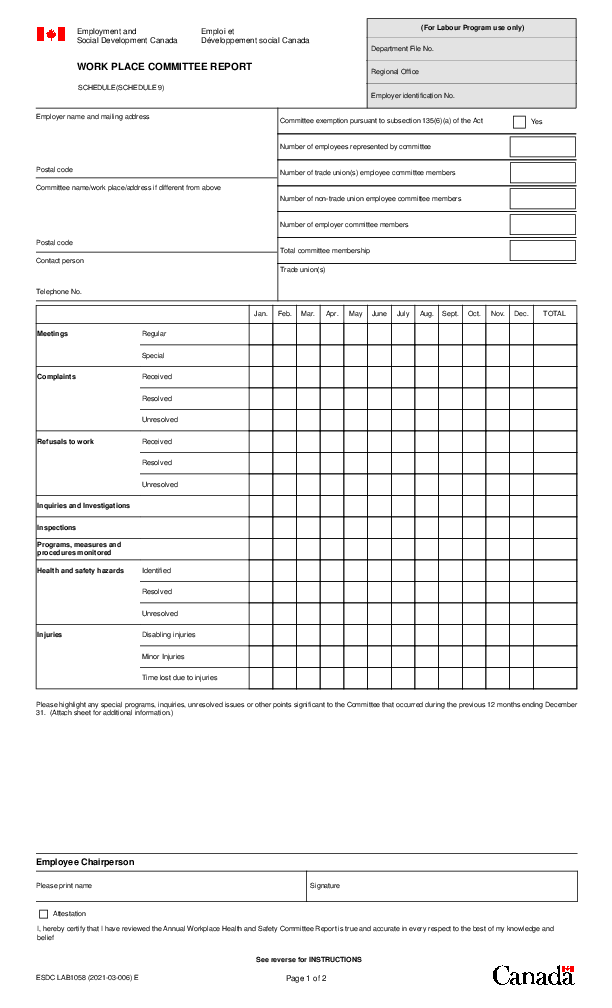

ESDC Workplace Committee Report

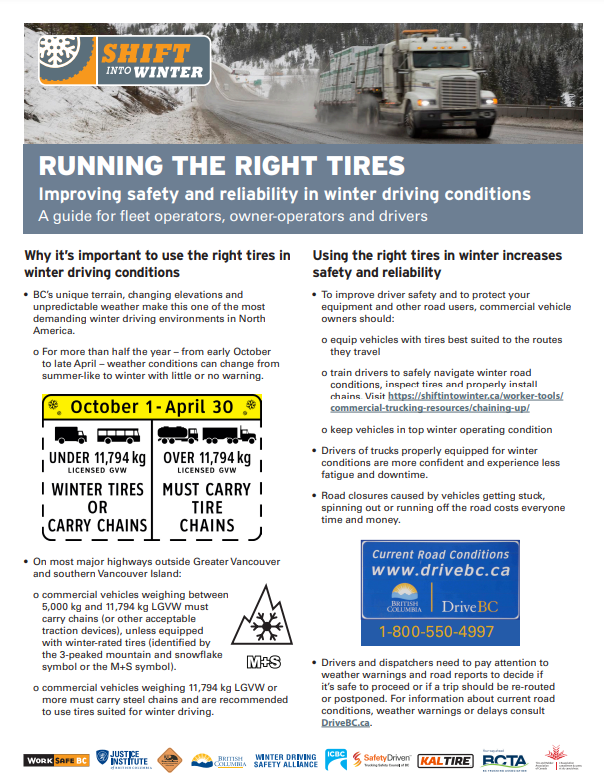

Running the Right Tires

Road Safety at WorkUse this guide for fleet operators, owner-operators, and drivers to help improve safe ...