How to Run an Effective Toolbox Talk

Let’s be honest: not everybody has the personality to be a trainer.

It’s easy to hand somebody some information and say, “Here, go teach this to your workers.” They might be able to rattle off that information to their audience, but can they do it in such a way that their audience will actually retain that information? Pre-job safety meetings, also known as “Toolbox Talks” because of their common use in the construction industry, are often performed on a weekly basis by a crew’s foreman or supervisor. These individuals don’t necessarily have any training or skills in training other people. Here are some tricks to the trade that can mean the difference between having your workforce learn some vital information and providing your workforce an extra 10-15 minutes of nap time.

Be Relevant

Nothing says it’s time to catch some shut-eye like an unrelated Toolbox Talk topic. Now, that’s not to say you can’t be creative with your training, but to completely miss the mark practically guarantees you will lose your audience. Can you do a toolbox talk on electrical safety when your particular crew isn’t working with anything electrical? Sure. Most likely they will work with power tools and extension cords at some point. Can you do a toolbox talk on steel erection fall protection regulations with your pipe crew? Sure, but why would you?

There is definitely something to be said for broadening one’s horizons, or getting an awareness of a topic so that your employees can spot hazards others might be encountering, but not at the cost of time that could be spent teaching them about something that is practical and relevant for them. Look for topics that apply to your crew. Observe them in the field to see which subjects seem to be in need of refreshing. If a near miss occurs or a dangerous situation is observed, use that. When your employees can personally relate to what is being discussed, it is much more likely to leave a lasting impression.

Be Engaging

This is what a Toolbox Talk sounds like to many employees: “Today we are going to talk about fall protection. Fall protection is a blah blah blah blah blah blah blah.” It doesn’t take long for an employee’s financial concerns, family issues, health problems, or plans for the upcoming weekend to creep into their mind when somebody is droning on. One way to prevent this is to use visuals. Don’t just talk about fall protection, have somebody don a harness and show everybody what is right and what is wrong about it. Don’t just talk about how much soil weighs, have your employees attempt to lift a crateful (using the proper lifting techniques, of course!). Show your maintenance crew how to use a new tool or machine. Safety is a physical thing, which makes demonstrations relatively easy to come up with.

Visuals are more engaging than lectures. Visuals encourage interaction. They use two of the employees’ senses (hearing and vision), rather than one. It’s a lot easier for us to tune out something we’re hearing than it is to ignore something we’re seeing.

Visuals aren’t the only way you can be engaging. The tone of your voice is important. Do you sound interested in the topic? Do you know what you’re talking about or are you reading it verbatim off a sheet of paper? Do you have any interesting stories to relate from your personal experience? Your enthusiasm will translate into employee enthusiasm. Your display of knowledge or experience will translate into credibility which is critical. Being boring isn’t the only reason employees might tune you out. If they don’t believe you are an authority on the subject, they are unlikely to give you the attention you’re requesting.

Involve Personnel

One of the most important things you can do to be engaging, is to not try to place the burden on your own shoulders week in and week out. Your employees will tire of your voice after a while, even if you’re the best trainer around. Find ways to involve the employees, whether by having them deliver the toolbox talks themselves or by having them volunteer personal stories that relate to the topic. Most importantly, ask them questions as you go. You could quiz them afterward, but by throwing a “At what height is fall protection required?” or a “Where do I find first aid info for a chemical exposure?” at them, you’re keeping them involved and attentive. The added bonus of this is you get to assess the employees on an individual basis. Who is constantly raising their hand? Who is trying to blend into the background? If you’re observant, your employees’ body language and behavior will tell you a great deal about what they do and do not know.

Manage the Meeting

Getting employees involved is important, but you also have to be careful to manage the meeting. What starts as a good educational session with a couple of personal stories shared to enhance the subject matter can quickly devolve into storytime or a gripe session if not properly managed. You may be turning some of the content over to your personnel, but you are still in charge of the meeting. It is important to keep it focused. Allow discussion, but when it starts to veer off course, jump back in and point it where it needs to go. If you have a guest speaker, make sure they’re staying on track for the time you’ve allotted them. Make the meeting fun, but keep it under control.

Toolbox Talks are about enhancing employee safety, not just being present long enough to sign an attendance sheet. As an employer, you should be making sure that whoever is providing the training is qualified to do so, so that your workforce is benefiting from it. One good toolbox talk could be the difference between life and death.

Check out some of our safety talks/toolbox talks here.

Stay up to date and sign up for one of our newsletters.

Latest Resources

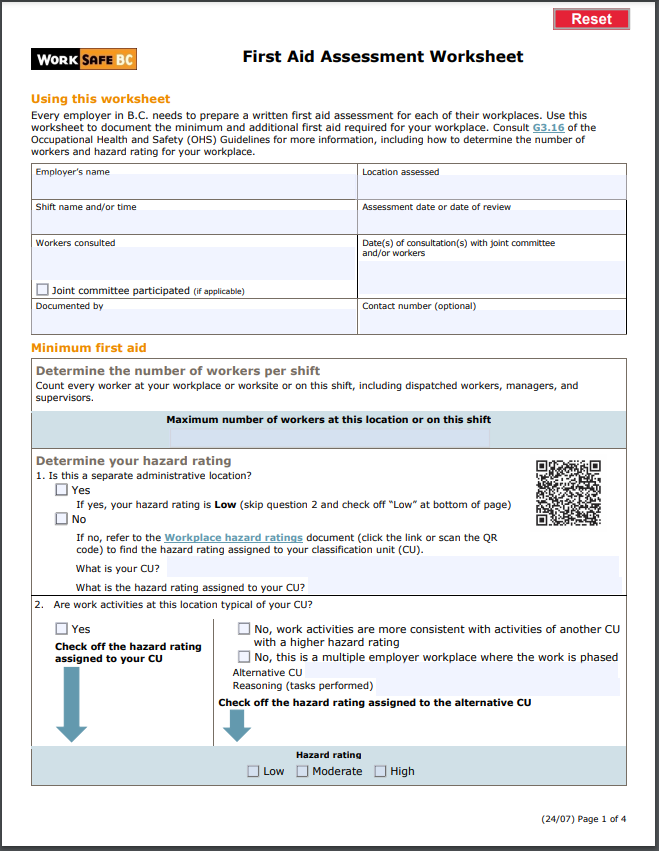

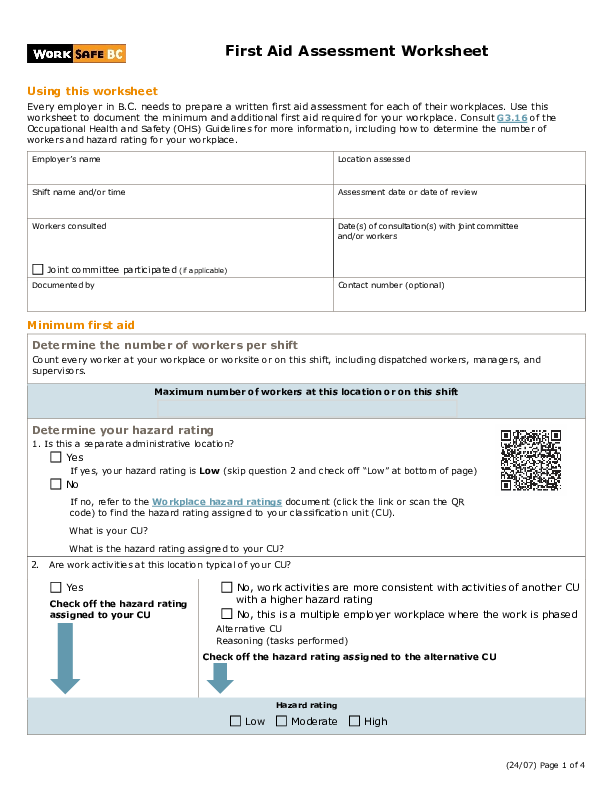

How to Complete WorkSafeBC’s First Aid Assessment

Learn how to complete WorkSafeBC's First Aid Assessment with this step-by-step guide. ...

First Aid Assessment Worksheet

Every employer in B.C needs to prepare a written first aid assessment for each of the ...