Heat Stress

How can workers prevent heat stress before it begins?

Longer hours and increasing climate levels are transforming work zones into dangerous heat zones. Ignoring early warning signs such as heat discomfort, sweating or thirst can lead to heat-related illness, including heat stroke and death. Planning and preparedness are no longer luxuries, but necessities, when it comes to heat-related illness prevention.

Although outdoor hazards may be the most obvious environment for heat-related illness risks, indoor workers can suffer from similar extreme temperatures. Regardless of the location, it’s critical to limit the risk of heat stress as much as possible. When elimination or substitution controls aren’t feasible, a combination of administrative controls and personal protective equipment are the recommended approach. The list of solutions may include:

Shade: One pre-emptive method to ensure workers are protected is to implement onsite areas that serve as a refuge from the heat. Within these “zones” should be easy access to shade, fluids for drinking, and an air-conditioned room or well-ventilated zone where workers can rest.

Hydration: Workers lose an average of 2-3 gallons of fluid per day through sweat while working in heat, so it’s important for workers to actively hydrate before, during and after their shifts. When replenishing, a worker should drink 2 cups of water for every pound lost during a shift. Additionally, monitoring urine color with a urine color chart can be an effective way of helping hydration stay a priority, as urine color is often the first sign of dehydration.

Remember, water is the best solution when maintaining fluid levels; however, if cramping occurs, electrolyte solutions should be substituted. Sugary drinks should be avoided because they can severely limit absorption of liquid in the body. Providing workers with personal hydration solutions (such as a water bottle) that they can carry with them to their jobsite (if conducive) will also help encourage hydration.

PPE: Personal protective equipment such as brimmed hats and light-colored material are two examples of reducing direct exposure to the sun and limiting worker susceptibility to heat-related illnesses. Additionally, incorporating fast-drying absorptive materials will help keep workers cool by increasing the rate of evaporation through trapping and quickly dissipating sweat.

Evaporative cooling bandanas, headbands and hard hat inserts keep workers cool using an evaporative cooling process that holds a cooler temperature than ambient air. Placing one of these products in an area where large blood vessels are located, including the neck, crook of the arm, groin or armpits, can keep workers’ core body temperature in check. Cooling vests also can be worn to help maintain a safe core body temperature, especially if an application requires workers to wear heavy protective gear.

Taking a few key steps to prevent a heat-related illness is far better than planning how to deal with it once it becomes an issue. Providing proper training, facilities, and PPE for heat-related illnesses; being aware of the early warning signs; and following steps to minimize workplace risks all are key components to keeping safety priority No. 1.

Latest Resources

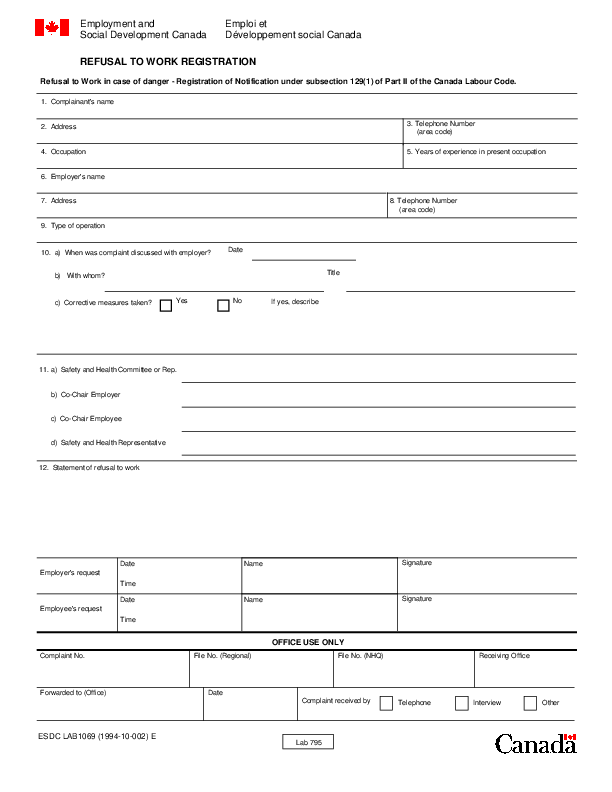

LAB 1069-Refusal to Work Registration

The Employer’s Investigation Report (LAB1069) is a required form under Part II of t ...

Joint Health and Safety Committee Evaluation Tool

This evaluation tool helps assess the effectiveness of a Joint Health and Safety Comm ...