The Trip Inspection Report and the Work Flow Process

Paperwork compliance and how it affects you.

The National Safety Code requires compliance to all aspects of fleet operations. The main process required by NSC is the trip inspection reports and how the paperwork is handled.

The first item of compliance is which vehicles are required to carry written inspection reports when on the road. The main vehicle types are any commercial vehicle over 14,600 kgs; any bus with a seating capacity of ten or more passengers—though this isn’t to be confused with the requirements for an unrestricted class four license (which is ten passengers, including the driver); and any vehicle that is designed to tow a trailer with a licensed Gross Vehicle Weight (GVW) of more than 8200 kgs.

The trip inspection report must be completed before the first trip of the day and at the first rest stop after midnight if the trip lasts longer than one day. A post-trip inspection must be completed at the end of the day and on every subsequent day of the trip when it lasts longer than one day.

All trip inspection reports have to be turned in within twenty days of when the trip is completed and must then be filed within thirty days. Pre-trips must be kept for at least 90 days (in B.C.) and longer in some provinces such as Alberta where trip inspection reports must be kept for six months.

Once the trip inspection report is received, it must be reviewed and any required work must be scheduled. The report must be copied and the copy filed with the work order for the repair made to the vehicle. All of these vehicle records must be kept for a minimum of three years.

Once any work has been done there must be a way for the driver to know the work has been completed. This can be as simple as placing a copy of the completed work order in the vehicle so the driver knows that the work was completed. Another option is to have a monthly maintenance log in the vehicle; all repairs large and small can be recorded in the Monthly Maintenance Log, including small repairs made by the driver and even greasing the vehicle. This is referred to as a closed-loop: the repairs reported, the repairs completed, and the driver being advised of the completed repairs. This process is to be recorded as a part of the required Vehicle Safety Plan for the fleet’s National Safety Code certificate.

Trip inspection reports must be completed by the person who does the vehicle inspection. A daily post-trip inspection of the vehicle is required as well, with the exception of trips lasting more than one day. The driver must complete a post-trip inspection of the vehicle on every subsequent day of the trip.

Some exceptions to the rules for trip inspection reports are emergency vehicles or vehicles rented for a single trip.

Remember: all vehicles registered under the company’s National Safety Code number must have a pre-trip conducted daily, but only the vehicles listed above must have a written trip inspection in the vehicle before the vehicle leaves for the first trip of the day.

The process for trip inspection reports and the workflow process is a must for all fleets to ensure that the Vehicle Safety Plans for the National Safety Code certificate are properly recorded and followed.

Latest Resources

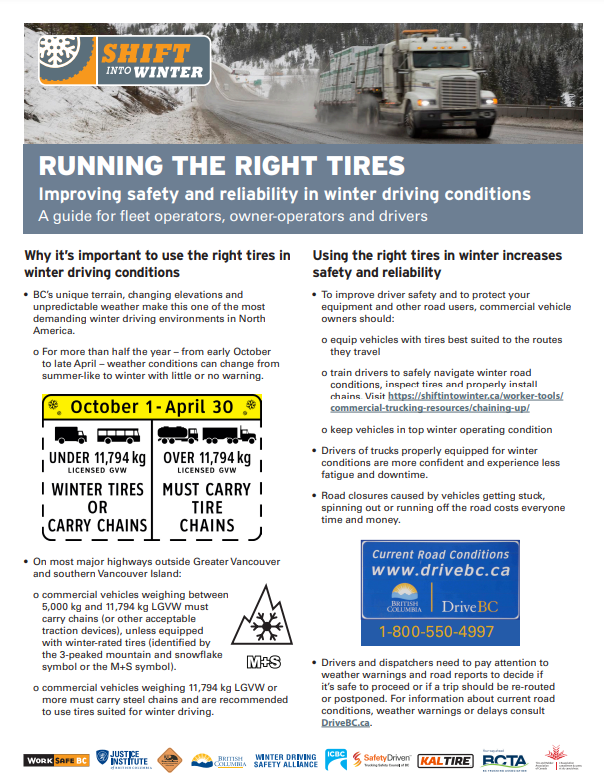

Running the Right Tires

Road Safety at WorkUse this guide for fleet operators, owner-operators, and drivers to help improve safe ...

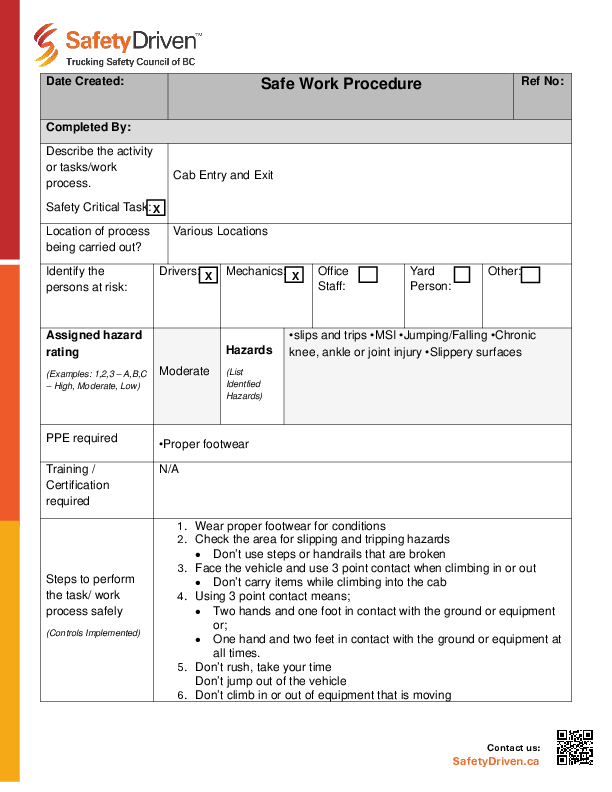

Safe Work Procedure: Cab Entry & Exit

An Employer can make use of a safe work procedure (SWP) by training new and existing ...